The Curious Case of the Exploding Windows

Not used as commonly as the word hazardous to describe building materials like asbestos, the word deleterious casts a wider net over what should have equal focus on them. The dictionary definition of deleterious is; “causing harm or damage”. In property, a material is considered deleterious when it doesn’t perform as expected, is a risk to life, often both.

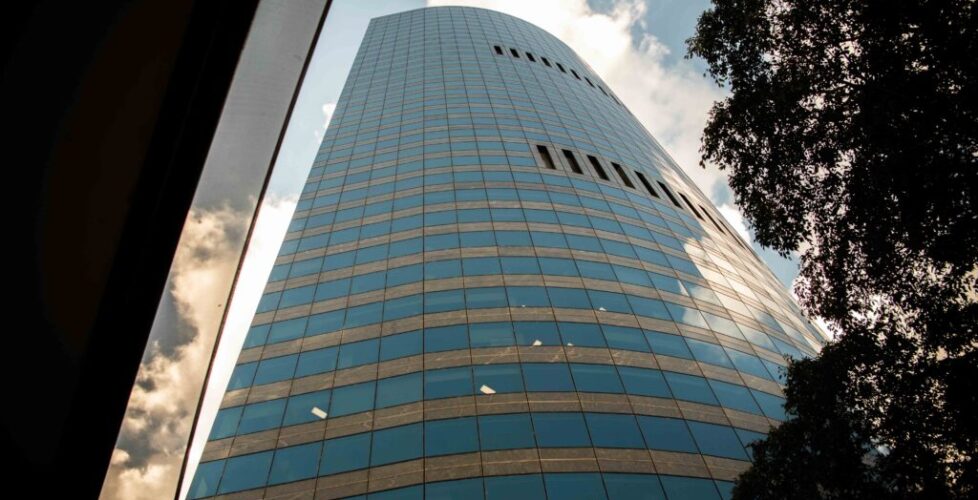

The site of what was once Brisbane’s original port dating back to 1879 is occupied by what was formally known as Waterfront Place now called One Eagle; a concrete framed, fully glazed, forty floor commercial office tower constructed in 1989. It was the location of my first project after I moved to Brisbane in 2013; the refurbishment of Hon. Bill Hayden AC’s office, the 21st governor-general of Australia. In June 2015, the building was bought by Dexus for $635 million AUD.[1] When Dexus purchased it, they didn’t have to rely on the technical due diligence report to unearth the issue with it’s glazing. News outlets had well documented the glazed panels which had been exploding off the side of the building since 1990.

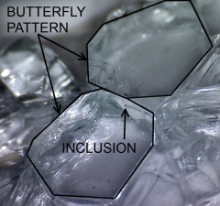

A nickel sulphide inclusion is one of over fifty types of glass inclusions, naturally formed impurities created from the glass making process. This type of inclusion only occurs in tempered glass and not annealed, or heat strengthened glass. Tempered safety glass is designed to break into hundreds of small cubes. Through glass fractography, the study of broken glass to understand failures, analysts found at the vocal point of the break created by a nickel sulphide inclusion, there’s a different pattern: a pair of multi-sided figures next to each other that look like a butterfly.

Between the border of these two polygons is a tiny dot. Barely visible to the human eye, that little dot is responsible for spontaneously exploding the entire sheet of glass in an instant. This shattering symphony takes place at over 4,800km/h or 3,000mph, all coming from one small inclusion that can be between 0.0762 millimetres and 0.381 millimetres wide. Temperature causes the inclusion to grow in size, eventually breaking the glass. They are too small to be detected in the manufacturing process. There is currently no technology that eliminates the possible formation of nickel sulphide stones in glass. There are however, controls that glass manufacturers implement to greatly reduce the likelihood of inclusions, like avoiding the use of nickel in any primary batch formations, banning nickel baring metals from all operations, and by using special plant and equipment such as magnetic separators.

Whilst it’s not possible to identify on a building inspection using the naked eye, where there are concerns which indicate a possible risk there is a photographic method which can be used to help identify possible inclusions. By using an appropriate macro lens at a resolution that will allow significant magnification. Being able to adequately collect and examine these images enters the realm of a construction science specialist. Glass manufacturers maintain that the risk of nickel sulphide inclusions forming is very small, estimating that incidents are 1 in 13,000kg of glass. One Eagle drew the short straw.

Between 1990 and 1997, One Eagle documented around 140 spontaneous failures, and on 68 of those occasions the nickel sulphide inclusion located at the initiation point was able to be recovered, analysed, and measured. The tower contains around 9,500 individual panes of glass, 4,194 of which were subject to a photographic investigation process which identified 53,594 inclusions, 291 of which were identified as nickel sulphide within 281 windows.[2]

(Special credit to Trevor Ford, a veteran building services engineer here in Brisbane. I had the pleasure of enlisting Trevor’s building detective skills to identify the source of a high frequency noise caused by a plant room motor by using multiple directional microphones. An issue that was at the heart of a noise compliant by a neighboring owner. I was surprised to find his work online, and grateful that it was publicly available to learn from).

Around 120 higher risk panes were replaced as part of a $1.6 million project.[3] Re-cladding the entire building was not financially or operationally feasible. Instead, as well as maintaining discreet exclusion zones around the base of the property, large canopies and shade sails were installed around the base of the building. To look at the port cochere and surrounding shading, one would think these are architecturally interesting and practical features sheltering visitors and vehicles from the hot Queensland sun and monsoon like rains. Whilst this is true, they have a far more important job: to protect those below by catching falling glass whenever a panel unexpectedly explodes.

The greater precinct, named Waterfront Brisbane, is set to continue to transform the city with the approval of a $2.5 billion which includes two new office towers, a riverfront retail precinct and expanded public space, including the widening of the riverwalk and a new destination dining experience. The development’s scheduled completion is 2028. Progress marches on.

CJLM

This is an excerpt from The Building Detective: Uncover building mysteries and solve them like a sleuth, a new book for problem solvers. Register your interest in a copy here: https://thebuildingdetective.com

[1] Johanson, Simon. “Dexus Snaps up Waterfront Place Tower, Eagle Street Pier Retail Site for $635m.” The Sydney Morning Herald, 22 June 2015, www.smh.com.au/business/companies/dexus-snaps-up-waterfront-place-tower-eagle-street-pier-retail-site-for-635m-20150622-ghu40b.html. Accessed 1 July 2024.

[2] Ford, Trevor. Spontaneous Fracture of Glass due to Nickel Sulphide Inclusions – Risk Management and Development of a Non Destructive Testing System.

[3] “Flawed Beauty: The Problem with Toughened Glass – IELTS Reading Practice Test.” Mini-Ielts.com, mini-ielts.com/222/view-solution/reading/flawed-beauty-the-problem-with-toughened-glass. Accessed 1 July 2024.